Crescent Yav Dhau Los Tshuab Ntawv Tissue High Speed

Cov Txheej Txheem Tseem Ceeb

| 1. Khoom siv raw | Cov ntawv dawb huv (ntoo ntawv, xyoob ntawv, straw ntawv); Rov ua dua tshiab Dawb Txiav |

| 2. Daim ntawv tso tawm | Qib siab Jumbo yob rau daim ntawv ntsej muag thiab daim ntawv so quav |

| 3. Qhov hnyav ntawm daim ntawv tso zis | 12-25g/m22 |

| 4. Muaj peev xwm | 25-50 Tons ib hnub |

| 5. Qhov dav ntawm daim ntawv | 2850-3600 hli |

| 6. Qhov dav ntawm hlau | 3300-4000 hli |

| 7. Kev ua haujlwm ceev | 500-1000m/feeb |

| 8. Tsim qhov ceev | 1200m/feeb |

| 9. Kev ntsuas tsheb ciav hlau | 3900-4600 hli |

| 10. Txoj kev tsav tsheb | Kev tswj qhov ceev ntawm lub tshuab hloov pauv zaus tam sim no, kev tsav tsheb seem. |

| 11. Hom qauv | Tshuab sab laug lossis sab xis. |

Cov Txheej Txheem Kev Txawj Ntse

Cov ntoo pulp thiab cov txiav dawb → Cov txheej txheem npaj khoom lag luam → Lub thawv taub hau → seem tsim hlau → seem ziab → seem reeling

Cov Txheej Txheem Ua Ntawv

Cov Kev Cai rau Dej, hluav taws xob, pa dej, cua compressed thiab lubrication:

1. Dej tshiab thiab dej siv dua tshiab:

Cov dej tshiab: huv si, tsis muaj xim, xuab zeb tsawg

Lub siab dej tshiab siv rau lub boiler thiab kev ntxuav system: 3Mpa, 2Mpa, 0.4Mpa (3 hom) PH nqi: 6 ~ 8

Siv dej dua tshiab:

COD≦600 BOD≦240 SS≦80 ℃ 20-38 PH6-8

2. Cov khoom siv fais fab

Lub zog: 380 / 220V ± 10%

Kev tswj hwm qhov system voltage: 220 / 24V

Zaus: 50HZ ± 2

3. Ua haujlwm ntawm lub zog ua kom lub tshuab ziab khaub ncaws ≦0.5Mpa

4. Cua compressed

● Qhov cua qhov siab: 0.6 ~ 0.7Mpa

● Ua haujlwm siab: ≤0.5Mpa

● Cov Kev Cai: lim dej, tshem roj, tshem dej, qhuav

Qhov kub ntawm huab cua: ≤35 ℃

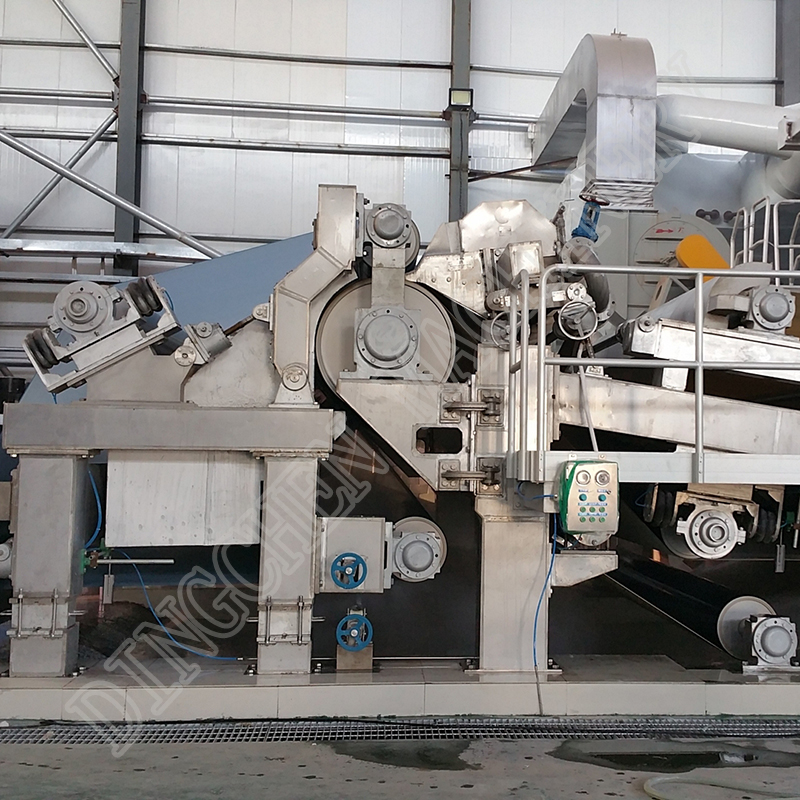

Cov Duab Khoom