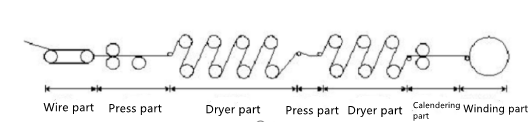

Cov khoom tseem ceeb ntawm cov tshuab ua ntawv raws li kev txiav txim ntawm kev tsim ntawv yog muab faib ua cov hlau, nias, ua ntej ziab, tom qab nias, tom qab ziab, tshuab calendering, tshuab dov ntawv, thiab lwm yam. Cov txheej txheem yog kom qhuav cov pulp tso tawm los ntawm lub taub hau hauv qhov mesh, nias nws hauv qhov nias kom ua rau cov ntawv txheej sib xws, qhuav ua ntej ziab, tom qab ntawd nkag mus rau hauv lub tshuab nias ntawm qhov loj me, tom qab ntawd nkag mus rau hauv lub tshuab ziab kom qhuav, thiab tom qab ntawd siv lub tshuab nias kom du daim ntawv, thiab thaum kawg tsim cov ntawv yob loj los ntawm lub tshuab ntawv. Cov txheej txheem feem ntau yog raws li nram no:

1. Tshooj pulping: xaiv cov khoom siv raw → ua noj thiab sib cais fiber → ntxuav → tshuaj dawb → ntxuav thiab tshuaj ntsuam → concentration → khaws cia thiab khaws cia.

2. Ib feem ntawm cov hlau: Cov pulp ntws tawm ntawm lub taub hau, faib sib npaug thiab sib txuas rau ntawm lub pwm kheej kheej lossis ib feem ntawm cov hlau.

3. Nias ib feem: Daim ntawv ntub uas raug tshem tawm ntawm qhov chaw ntawm lub vas yog coj mus rau lub menyuam uas muaj daim ntawv ua ntawv. Los ntawm kev rho tawm ntawm lub menyuam thiab kev nqus dej ntawm daim ntawv, daim ntawv ntub raug qhuav ntxiv, thiab daim ntawv nruj dua, yog li txhim kho qhov chaw ntawm daim ntawv thiab ua kom muaj zog ntxiv.

4. Qhov chaw ziab khaub ncaws: Vim tias cov dej noo ntawm daim ntawv ntub tom qab nias tseem siab txog 52% ~ 70%, nws tsis tuaj yeem siv lub zog kho tshuab kom tshem tawm cov dej noo, yog li cia daim ntawv ntub dhau ntawm ntau qhov chaw ziab khaub ncaws kom qhuav daim ntawv.

5. Qhov cua ntawm daim ntawv: Daim ntawv yob yog ua los ntawm lub tshuab cua ntawv.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-18-2022